Flexible and reliable – laminate tubes

Did you know that laminate tubes are indispensable for a successful start to the day? Shower gel, shampoo, toothpaste, shaving gel, body lotion, make-up and hand cream – most of these products are packaged in laminate tubes for a reason - tubes made of PBL or ABL laminate offer comfortable handling, are insensitive to moisture, and are easy to open and close again. They are flexible,unbreakable and portioning is easy.

Laminate tubes are made of several interconnected substrate layers made of plastic, which are bonded together by lamination and protect products from water, UV light and oxygen. For a classy look the material can be printed and finished in high-quality digital printing.

The difference between ABL and PBL tubes

There are two types of printable laminate tubes: ABL tubes made of aluminum barrier laminate and the PBL tubes made of plastic barrier laminate. Both variants have an efficient barrier layer that protects the tube contents from environmental influences and enables a long shelf life without loss of quality.

The ABL-Tube has a thin aluminum layer between the individual plastic layers - the barrier properties of aluminum also meet the high requirements of pharmaceutical products and cosmetics.

ABL laminate tubes have barrier properties that were previously predominantly attributed to extruded plastic and pure aluminum tubes and can therefore be assigned to the high-barrier segment.

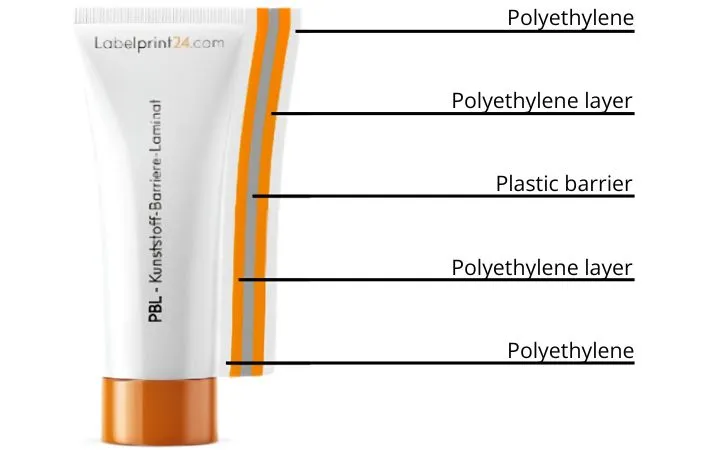

In comparison, the PBL tube is entirely made of plastic. The laminate of this laminate tube also consists of several layers of high-density polyethylene (HDPE) - in contrast to aluminum, the barrier layer here is made of EVOH (Ethylene Vinyl Alcohol). EVOH is a copolymer with optimal barrier properties against UV light, oxygen and aromas. Both types of tubes offer efficient product protection and perfectly functioning barrier and hygiene properties.

Due to the limited recyclability of composite materials, mono-materials will increasingly be used in tubes in the future. In these sustainable tubes, the tube, shoulder and closure are also made of PE. In addition to increase the recyclability of the materials, thinner wall thicknesses to reduce material, the avoidance of tube and shoulder coloration and the use of recycles are also effective measures for greater sustainability.

The advantage of printable packaging

Modern laminate tubes are manufactured using digital printing processes, which makes it easy to personalize and individualize the tubes. This means that even small, personalised runs of cosmetic, pharmaceutical, dental or promotional product tubes for flexible market tests or seasonal items can be realised at low cost. In addition, there are fast production and delivery times of three weeks for standard products, as well as the possibility to order tubes from certain suppliers from a quantity of 1000 pieces. In addition to matt and glossy varnishes, which make the printed image even more attractive and protect the surface of the laminate from damage, laminate tubes can also be finished with metallic foil. Thanks to the 360° printing, the tubes offer a great deal of creative freedom in terms of design and, in addition to their advantages as product packaging, are also ideal as an information and advertising medium.

With the use of CMYK colours, photorealistic print images are possible in digital printing, even in short runs, as there is no need to create individual printing plates for each printing ink used. Especially for small and medium-sized cosmetics companies, digital printing offers another advantage: It enables runs of 1000 or 3000 pieces or more - in addition, orders can also be staggered according to grades. For example, a total circulation of 12,000 copies can be divided into three varieties of 4000 copies. This allows three different designs to be produced in one order. On the other hand, digital printing also makes it possible to produce large runs of many different types in a short time. For a simple ordering process, some tube manufacturers offer an online order form in which the tubes can be configured and calculated directly. In combination with digital printing, this leads to great time savings in ordering and production. This means that tubes can be delivered to customers as early as three weeks after ordering.

The manufactoring process

The laminate tubes are manufactured on a so-called tube system or tube line – here, individual tube bodies in various lengths and diameters are formed with the highest precision from a flat, digitally printed laminate roll. The tube system itself consists of several successive workstations: a welding machine, tube shoulder production and an integrated screw-on unit for various types of caps.

After inserting the printed laminate roll into the roll seat of the system, the flat laminate is bent into a tube and the two opposite edges are welded together to form a fixed tube seam. A rotary knife cuts the tube to the respective tube length, creating the so-called “tube body”. In the next step, the tube shoulder is threaded onto the tube body and both components are firmly connected to each other by adding heat or induction. Optionally, a freshness seal can be affixed to the thread of the tube shoulder. In the screw-on unit, the tube closure is finally twisted onto the tube thread or bruised. The laminate tubes are shipped open and upright to allow the contents to be filled directly. After filling with paste-like liquids, e.g. cream, lotion or shower liquid, they are welded at the open end, whereby the heated plastic layers fuse together to form a solid bond. This means that the laminate tubes are ready for use as shampoo or toothpaste tubes.

Their field of application is not limited to the cosmetic or pharmaceutical sector. Tubes made of plastic laminate can be found in many industries and are used as packaging for foodstuffs as well as for adhesives, lubricants, cleaning pastes, pet food and many other products.